◀ Back to projects overview P201203-007-BN

Alternative foundation connection

Main objectives of the project

In search of cost reduction in offshore wind energy, a conceivable option is to substitute the commonly used grouted transition piece with an alternative connection method, thereby reducing both costs and risks. This study focuses on the ‘welded’ connection as an alternative connection.

The original main objective of this research was “to decrease existing risks and uncertainties involved in a welded connection between transition piece and monopile to an acceptable level”.

Approach and results obtained

The study is in principle neither meant as a fundamental study to eliminate the grouted connection nor as a systematic search for the best (alternative) foundation connection method. This research is in the first place meant to investigate one specific method (other than grouting) to connect a monopile (to the transition) to the turbine tower, namely: welding (offshore).

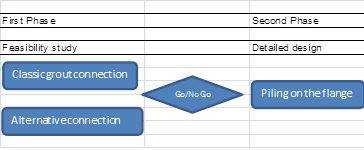

Three main engineering reports are produced, one for each phase: 1A, 1B and 2.

The Phase 1A report investigates the technical feasibility of the welded connection concerning the welding method, specifications and limitations.

The Phase 1B report investigates and compares the financial feasibility of the three connection types: the grouted, the welded and the flanged connection. Off all these connection types the CAPEX is evaluated including installation cycle times and installation risks of the foundation connection. The result of the study was that the cycle time of the grouted connection was the shortest and the CAPEX for the flanged connection was the lowest.

In the course of the project it became apparent that the alternative of ‘piling on the flange’ was more favourable than the ‘welded’ connection. Therefore this solution is chosen as preferred option and further detailed in phase 2.

Summary of the FLOW Alternative Foundation Connection research

In the third report, the Phase 2 report, the method of piling on the flange is described for an actual project and for which three sub-reports have been prepared of which one is certified by DNV and the others by an internal validation of BNE. The outcome of these studies can be summarised as follows:

‘Piling on the flange’, whereby the monopile with flange is piled down as a whole and the weld is laid in factory instead of offshore, is more cost effective. Only the access platform and boat landing have to be installed offshore.

Driving on the flange is technically feasible. In general it can be concluded that significant more engineering time is required for a driving on the flange design, that larger wall thickness top cans is required, to use as little driving energy as possible (per blow) to reduce the driving fatigue damage, which results in more blows per pile installation and to improve the flange design in close collaboration with the tower supplier.

Contribution to cost and risk reduction of far offshore wind energy

As concluded in the Phase 1B report the CAPEX of the piling on the flange solution is two third of the CAPEX of a grouted connection, although the installation time is almost 20% longer.

Accordingly the CAPEX of the welded solution is 5% higher compared to the grouted solution, and the installation time is more than six times longer.

The savings of piling on the flange for the LCoE for a complete wind farm are 2,8% compared to a wind farm with only grouted connections.

The LCoE for a wind farm with monopiles with only welded connections is 1,6% higher than a wind farm with grouted connections, although the risks of the grouted connection is eliminated.

The piling on the flange method is more cost effective and reduces important risks: a reduction of the environmental, quality and time risks (of the grout operation) and risk of failure of the (grouted) structure during its lifetime; however this method also introduces two other risks: a potential inclination of the foundation, which, if out of tolerance, has to be corrected (with a ‘wedge’ or ‘banana’) before installing the tower, and yet possible fatigue lifetime effects, which could be substantial, and are unknown, with very large (>6m) diameter piles. For this reason for large diameter piles (offshore) welding might still be a cost effective option.

As a result of this project the “piling on the flange” method has successfully been applied on the Westermeerwind project in 2015.

Partners involved

Ballast Nedam

Contact details

Mr. Dolf Elsevier van Griethuysen

Share this page

Share this page