◀ Back to projects overview P201305_008_ENE

Free Hanging Cables

Public summary

Wind turbine foundations comprise a significant part of the capital expenditure of an offshore wind farm. As such, the opportunities of substantial cost reduction exists in novel wind turbine foundation designs. Any new design will have to go through a process of maturation before wide spread adoption in the sector is possible.

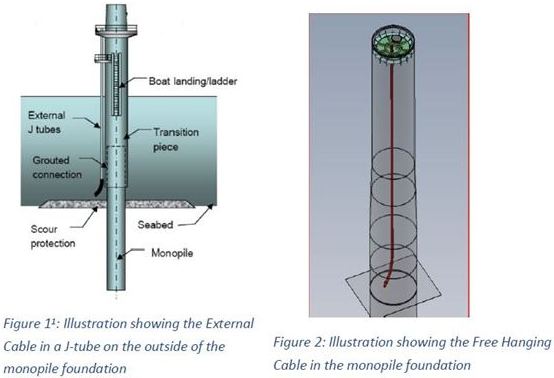

This FLOW project aims at maturing a particular foundation design concept: the use of infield cables which are routed inside the monopile and are hanging freely. The free hanging cable project for the Eneco Luchterduinen windfarm was conducted in order to demonstrate that the free hanging cable (Figure 2) is a better alternative to the J-tube, which eliminates the cost of J-tubes (Figure 11) and reduces primary steel, while not requiring significant additional investments, nor introducing significant risks.

A number of engineering studies have been conducted prior to the detailed design of the free hanging cable to assess the feasibility of the concept. The engineering studies include a global analysis of the concept with respect to fatigue and dynamic behaviour, a study on the heat transfer characteristics of the cable and the cable protection system and a local analysis of major components in the cable and cable protection system. It was found that the design of the free hanging cable did not introduce any significant risks.

Prior to the installation, pull-in and burial of the inter array cables and cable protection systems, a general method statement was prepared by van Oord containing the typical description of the works associated with the installation and burial of the inter array cables. The installation of the free hanging cables was a success and omitted the need for the installation of J-tubes offshore, thereby reducing costs.

Currently a monitoring campaign is ongoing to assess the operational behaviour of the free hanging cable. The monitoring of the free hanging started in November 2015 and will continue for three years.

Prior to the start of this FLOW project, the free hanging cable design concept was at a Technology Readiness Level of 7, (demonstration of the system operating in an operational environment at pre- commercial scale) as there were few offshore wind farms under construction or operational where the free hanging cable solution has been implemented, and some key studies were not yet executed.

Based the positive results of this FLOW project, and the wider implementation of the free hanging cable in other wind farms, the free hanging cable design has reached TRL level 9: Commercially available.

In summary the project has demonstrated that the free hanging cable is a cost-effective design option for the routing of inter array cables in monopile foundations.

Partners involved

- Eneco

- RWE

- Van Oord

Project documents

![]() BPP Global analysis report fatigue analysis

BPP Global analysis report fatigue analysis

Share this page

Share this page