◀ Back to projects overview P201406_004_WMC

Improved Offshore Wave Load Simulation

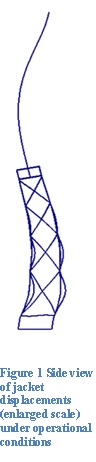

Large offshore wind turbines are built on support structures. These structures carry the weight of the wind turbine and support the forces exerted by wind and water. For near-shore turbines it is current practice to use monopile support structures, but for larger water depths further offshore, jacket support structures are considered as an alternative. The forces applied by wind and waves to the wind turbine and jacket result in deformations in the support structure. This elastic behaviour of the turbine and support structure causes fatigue damage to the structure. In Figure 1 a side view is shown of a jacket under operational conditions (the displacements are exaggerated for reasons of clarity). Simulating the elastic behaviour of a wind turbine is complex, as wind and wave loads, elastic deformations of turbine blades and support structure, and controller operation all interact.

For accurate simulations, Finite Element (FE) models can be used. These models are computationally demanding. Therefore, state-of-the-art integrated wind turbine design software makes use of methods to reduce the complexity of the full Finite Element support structure model for the time-dependent aero- and hydro-elastic analysis of a wind turbine and support structure system. Verification of simulation results in previous benchmark projects has shown that global turbine response is simulated satisfactorily.

However, results of earlier research projects indicate that the wave and current loading on the individual members of a jacket tower are not covered sufficiently by using the global description inherent to reduced-system solutions. The modelling of local wave and current loading in integrated design tools needs to be improved without sacrificing the efficiency of reduced-system simulation tools. In this project improved wave modelling is implemented in the integrated wind turbine design tool FOCUS6.

Objectives

The main objectives of the project are:

- Validate the implementation of the hydrodynamic modelling in the FOCUS6 turbine design tool by means of comparison with experimental data available in the IEA OC5 project.

- Modify FOCUS6 to allow advanced modelling of wave and current loading on individual members of a wind turbine support structure.

- Provide guidelines on best practices for the level of detail required in support structure modelling for specific load cases. These will be based on a study using a turbine model provided by XEMC Darwind and a representative support structure model.

Approach and results obtained

In order to improve the modelling of wave loads on support structures, a good understanding of numerical aspects relevant to implementation of the hydrodynamical model is required. Therefore the first part of the research has been dedicated to validating the existing hydrodynamic model implementation in PHATAS, the aero- and hydro-elastic simulation tool included in the FOCUS6 package. Validation has been done using experimental wave tank test data on cylinders, as part of the IEA OC5 project. The comparison with measurement data showed that the implementation of the hydrodynamical model in PHATAS leads to accurate predictions of the hydrodynamic force on a cylindrical structure. The results produced with FOCUS6 matched those of other participants using a similar implementation in their codes.

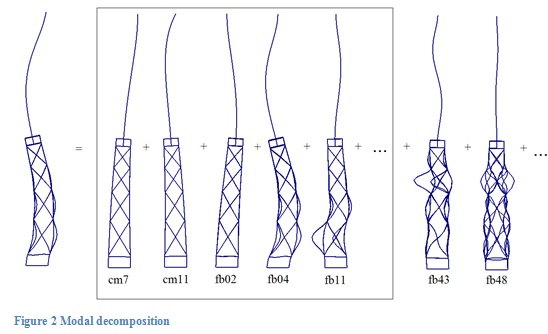

As stated in the introduction, current state-of-the-art integrated design tools accurately predict global behaviour of the turbine support structure, but discard information that is important for accurately determining wave loads on individual support structure members. In this project, a new method has been developed for computing wave loads on wind turbine support structures in integrated design simulations. This method evaluates the wave loads in a finite element (FE) model. The wave loads are separated into components responsible for the different vibration shapes of the support structure, as shown in Figure 2. The vibration shapes are divided in two groups. The first group, shown in the rectangle in the figure, suffices to describe the global behaviour of the support structure, and the associated wave loads are called the modal wave loads. The second group of vibration shapes is associated with the remainder of the wave loads, called the surplus loads for brevity[1].

The modal wave loads are passed on to the wind turbine simulation program to determine global wind turbine behaviour. It is assumed that the surplus loads have no significant influence on the global wind turbine behaviour. The finite element program then uses the global wind turbine behaviour to assess the total wave loads, and subtracts the modal wave loads to obtain the surplus loads. The response signal components due to the global wind turbine behaviour are determined, and the response signal components due to the surplus loads are determined. Added together, these signals capture the detailed behaviour from the surplus forces and the global behaviour from the wind turbine simulation.

A study has been performed on a representative turbine (the XEMC Darwind XD115) and support structure combination (designed by Rambøll for the OC4 project) to compare the newly-developed advanced wave and current loading tool to current state-of-the-art reduced-system tools.

From this study the following can be concluded:

- For the considered support structure, the improved method can find an additional 30% in total fatigue damage, depending on the location of the member considered. Extreme load cases can feature stresses increased by up to 57%.

- The surplus force effects are most severe in the operational load cases among the fatigue load cases. For the extreme load cases, the 50 year recurrence load cases are most affected.

Evaluation of the wave and current loads on a 3D structure involves additional computational effort. In the initial design stages, it is recommended to apply the improved method on the most affected load cases only, and to apply the traditional method with a generous safety factor elsewhere. As the design process advances, more load cases can be evaluated using the improved method.

The improved wave load simulation method presented in this report looks to be a promising addition to traditional integral simulation methods. In the present project it has been compared to a traditional method that was validated using monopile wave tank tests. It is recommended to further validate the new method by taking part in the proposed Phase III of the OC5 project, scheduled for 2017, in which participants will validate their codes with full-scale jacket measurement data.

Contribution to FLOW targets

The FLOW R&D line 4.2 “Design and control tools” specifically identifies wave and current loading capabilities as an area of improvement for design tools. Within this project, an improved method for the inclusion of wave and current loading in the integral design and analysis of wind turbines and offshore support structures has been developed and implemented. This will allow designers to more accurately predict loads on offshore wind turbine structures, leading to a more reliable and cost-effective design.

This increase in reliability of the support structure design contributes towards the FLOW target of risk-reduction of offshore wind energy. Lower risks will contribute to an acceleration of deployment of offshore wind energy. With estimates for the decrease of support structure O&M costs and of wind turbine downtime caused by unscheduled maintenance, the FLOW cost model predicts an overall reduction of the Cost of Energy of slightly over 0.2%.

Contact details

Mr. Ben Hendriks

Share this page

Share this page