◀ Back to projects overview P201406_010_2BE

Increase Rotor Diameter

2-B Energy is developing a dedicated offshore wind turbine with a lower Cost of Energy (CoE) based on: a full jacket support structure concept with integrated design of support structure and foundation; suitable for large distance from the coast with helicopter access; sophisticated control system to reduce dynamic and extreme loads; and optimized for high availability by efficient service & maintenance & repair. The turbine is categorized as a 6MW, downwind operating, 2 blade horizontal axis wind turbine. The turbine is referred to as 2B6.

This project was initiated after “Upgrade to 140 meter rotor diameter on a two-bladed downwind turbine”, FLOW Project P201204-001-2BE. This project will be denoted as Project ‘130m to 140m’. The results of that FLOW Project showed significant reductions in cost of energy. This project focusing on the upgrade of the design towards a rotor diameter beyond 150 meter aiming at: “Improving the 2B6 design to lower the cost of energy”.

Main objective of the project

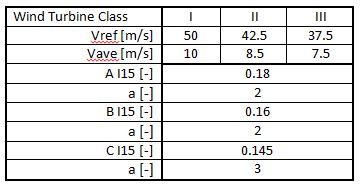

2-B Energy will investigate the increase of the rotor diameter suitable for both Class I and Class II sites, aiming to achieve an reduction in cost of energy (CoE) of at least 3.5%, compared to the 140 m diameter design, for a wind turbine class I site, and 5.3% for a Class II site, using similar Rotor Nacelle Assembly (RNA) components as the 2B6 design with a 140 m rotor diameter. Table 1-1 shows the basic parameters for Wind Turbine Class Definition of Germanischer Lloy’s “Guideline for the certification of Offshore Wind Turbines.

Obtained results of the project

In this project the initial evaluation of an increased rotor diameter of the 2B6-150+ turbine has been performed. The current 2B6-140 design has been finalised and is installed in Eemshaven, Netherlands as part of the onshore demonstrator project. The onshore demonstrator project demonstrates the feasibility of the offshore wind turbine concept of 2-B Energy. On 18th of December 2015 a major milestone was achieved by the first production of electricity during the commissioning phase of the wind turbine.

Current evaluation mainly focussed on the aero-elastic design of the larger rotor blade and its impact upon the loads. The current 68m blade has been scrutinised to identify the strenghts and weakneses. During the project it was decided to increase from a 68m blade towards a 75m blade, increasing the diameter of the turbine from 140m towards 155m. This extended blade has been evaluated by means of load evaluations and design reviews.

In addition to the aerodynamic design and evaluation of the larger blade, 2-B Energy has set-up a work package to identify multiple innovative control strategies with the goal to optimise the load levels for the increased rotor diameter. The goal of these control features was to maintain the same load level of the components of the 2B6-Gamma design at the larger rotor diameter. Maintaining similar load levels reduces the amount of components to be redesigned. Together with TU Delft a control package was set-up regarding “Iterative feedback tuning of feedforward Individual Pitch Control (IPC) for two-bladed wind turbines: A comparison with conventional IPC”. This work packages showed that these innovative control strategies have the potential to maintain the loads.

Contribution of the project results to cost and risk reduction for Far-offshore wind energy

The project resulted in an estimated reduction in Capital Expenditure (CAPEX) and the increase in Annual Energy Production (AEP) for this project are quantified as:

CAPEX an increase in blade mass of 4% due to extended blade length

AEP yield increase of 10% due to larger rotor diameter. [1]

The AEP increase outweighs the CAPEX increase which is reflected in the cost of energy calculation. The Cost of Energy reduction was quantified by using the FLOW Cost Model which results in a reduction of CoE of 8.81%. This calculated reduction is valid in case the overall CAPEX and OPEX of the design (structural components, electrical components) will stay equal.

Although the comparison made here is between two 2-B Energy concepts/designs, the results achieved could also be applicable in a broader sense since the increase in rotor diameter can be applied to other turbine designs to improve the annual energy production.

This project focused on the cost of energy reduction. The objective of this project to decrease the Cost of Energy with at least 5% is achieved. Significant cost of energy can be realized by extending the blade length and design optimizations.

Please visit the website of 2-B Energy for more information: www.2-benergy.com

[1] As a rule of thumb, the rotor diameter squared times a factor describing the effectiveness range, i.e. above rated power conditions no additional power is produced with a different rotor diameter. As axample (1552/1402 -1) x 40% = 9%.

Contact details

Mr. Jan Beerens

Share this page

Share this page