◀ Back to projects overview P201204-002-XD

Optimizing the cost of energy of the XD offshore wind turbine

Public summary

Objective

The main objective of this project has been: optimize the current XD115 wind turbine for integral cost of energy utilizing the latest control and supply chain capabilities.

The design of the XD115 was according to the technical and supply chain capabilities valid in 2007-2010. The wind turbine was equipped with a conventional wind turbine controller. The development of advanced control algorithms, however, has reduced rotor loads. This loads reduction and the advance of the supply chain has made it possible to increase rotor area, while keeping loads in check, lowering cost of energy.

This project has been expanded with another FLOW project (P201305-007-XD), titled: Extension Optimized 5 MW XD-WTG: Improved design and O&M.

Results

This project has successfully optimized the existing XD115 5MW offshore wind turbine for lowest cost of energy. This resulted in two new turbine designs: the XE128 5MW, of which a first offshore wind farm of ten units is being installed now in China (see Figure 1), and the XE140 4MW, which will be marketed for both onshore and offshore. Both are expected to be certified by DNV-GL in 2016-2017. Both designs have a lower cost of energy than the XD115. The intellectual property of the XE128 for Taiwan has also been sold to a Taiwanese consortium. It will be certified for wind class 1A to withstand local conditions.

While the rotor diameters and thus the energy yields have increased significantly with respect to the XD115, the loads have risen to a lower extent. To achieve this, advanced controller techniques have been researched and used if and where they added value. Individual pitch control has been researched and shown by Delft University to reduce flapwise blade moment fatigue loads by around 20%. This technology, and the mentioned fatigue load reduction, has been demonstrated successfully in practice by XEMC Darwind (XD) by implementing a new IPC controller for the XD115 and performing a measurement campaign. Extreme event control and fault-tolerant control (developed by ECN) have also been investigated and applied, reducing extreme loads. These innovations taken together provided the desired load reduction to be able to increase rotor size.

Contribution to FLOW

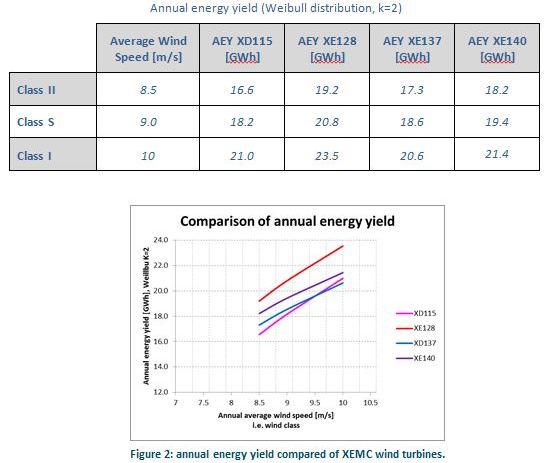

The results of this project are two wind turbines (XE128-5MW and XE140-4MW) which both have a higher annual energy yield (AEY) and a lower levelized cost of energy compared to the XD115. The AEY of the XE128 turbine increased about 12-16%, depending of the average wind speed. The AEY of the XE140 increased around 7-10%.

In the XD-XXX Extension project (P201305-007-XD), the designs of XE128 and XE140 have been made more robust as well. This led to a higher reliability and availability, further increasing the energy which can effectively be produced by these turbines. This has not been taken into account in the numbers above.

The levelized cost of energy (LCOE) reduction realized in this project with respect to the XD115 base case has been quantified at -6.8% for XE128 for case D and at -1.2% for XE140 for case E. Note that these results depend on the wind climate. The XE140 will perform better at sites with a lower average wind speed.

Concluding, XEMC Darwind, together with its partners, has used the FLOW support to realize two new turbine models with lower cost of energy than the previous one. This helps to bring the goals of lower cost of energy and rapid large-scale offshore implementation within reach.

Links

Partners involved

- ECN

- IHC

- TU Delft

- XEMC Darwind

Contact details

Mr. Marco Plantema

Project documents

Share this page

Share this page