◀ Back to projects overview P201102-004-ECN

Wind Farm Wake Modelling, Fatigue Loads and Control

Public summary

Wind turbines, when placed in a group, called wind farm, interact with each other through their wakes. The wake of a wind turbine is the result of its energy extraction from the flow and typically contains, amongst others, a reduced mean wind speed (deficit) and an increased wind speed variation (turbulence). These phenomena result in a decrease of power production and an increase of the loads at the leeward wind turbines that are operating in the wake.

But how does the flow in a wind farm develop? What loads has a wind turbine to endure in a wind farm setup? How can wind turbines be operated in a wind farm to reduce the wake losses and the loads? These questions have been addressed in this project on wind farm wake modelling, fatigue loads and control.

Objectives

This project aimed at reducing the cost of offshore wind energy by reducing the uncertainty in wind farm analysis (better wake models, accurate fatigue loads estimation) and improving the effectiveness of wind turbines operating in a wind farm (farm control strategy). To this end, the following three objectives were defined:

- To improve wake modelling to be used in the wind farm analysis code FarmFlow. This has been based on existing as well as new measurements and numerical results. The high fidelity method ECNS has been completed to aid the model improvement.

- To develop a method for estimation of fatigue loads on the wind turbine components operating in a wind farm. This module has been added to the wind farm analysis code FarmFlow, which enables to take the influence on Cost of Energy (CoE) of wake and electrical losses, loads and control all into account during the design.

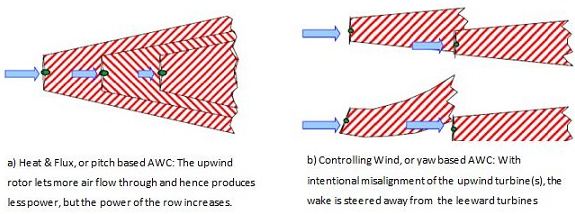

- To analyse and develop the two Active Wake Control (AWC) strategies Heat&Flux and ControllingWind by means of experimental and numerical techniques. The potential gain to increase of energy production and load reduction has been quantified.

Approach and results obtained

This section contains the approach and results per objective.

Wake model improvement

When operating in a wind farm, the wake behind a turbine will influence the inflow of the leeward turbine(s). As such, the wake model in wind farm analysis codes is essential for accurate prediction of the wind farm energy production. The approach taken is to use results from high fidelity numerical models and experiments as basis for model improvement.

The following results are achieved:

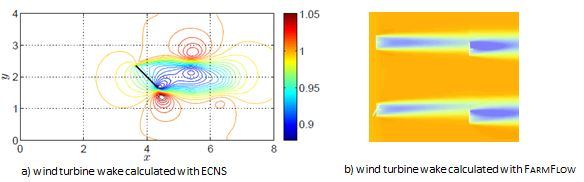

- The Computational Fluid Dynamics (CFD) method ECNS has been finalized, which has as unique feature its energy conserving numerical scheme.

- The near wake model, atmospheric stability, and the engineering model for yawed operation have been improved and included in FarmFlow, leading to reduction of uncertainty of the predictions of power and flow characteristics.

- FarmFlow has been accelerated: calculation time has been reduced by a factor 20, without noticeable reduction in accuracy compared to measurements.

The above figures show wake calculation with ECNS and FarmFlow, for a prescribed yaw misalignment.

Fatigue load estimation

The wake conditions of an upwind turbine should be taken into account when analysing wind turbine loads in a wind farm. To prevent the number of calculations to explode, the approach taken is to generate a load database for different wake characteristics. This database can be interpolated to find the loads for a specific wake situation.

The database has the following properties:

- Detailed wake characteristics, including wind speed, turbulence, shear, wake depth, wake width and wake position

- Two use modes of operation: detailed analysis (most accurate, time consuming) or scoping (fast, accuracy depends on similarity of the wind turbine design with the generic model)

After a FarmFlow calculation, the database can be called with the wake characteristics calculated from the flow field to find to loads for the specified cases.

Farm control strategies

Conventional control of stand-alone wind turbines aims at maximizing its own power production. When wind turbines are placed in large wind farms, the power production of the farm as a whole can be improved using wind farm control strategies. As part of this project, farm control strategies have been analysed and further developed, with focus on the ECN patented methods Heat&Flux and ControllingWind (both part of Active Wake Control).

The results of this part are summarized below.

- Based on a literature review and industry input, the primary optimization target is defined as maximizing the power production, while the loads remain within the design envelope.

- A code to optimize the Active Wake Control (AWC) settings based on FarmFlow simulations has been developed and stored under version control.

- Implementation issues have been addressed, which resulted in a condensed control strategy that fits with the application requirements by industry.

The improved and extended wind farm analysis code, including fatigue load module, has been applied in two test cases for the optimization and evaluation of AWC. The improved wake models, increased calculation speed and accurate loads estimation are all key to successful evaluation of the wind farm control strategies. The results indicate that for a typical large offshore wind farm, up to 10% of the wake losses can be recovered with AWC, while fatigue loads do not increase significantly.

Contribution to the FLOW targets

This project contributes to the reduction of the overall cost of energy by influencing the energy production (wake losses), the CAPital EXpenses (CAPEX) and the Weighted Average Cost of Capital (WACC). Indirectly, the Operation and Maintenance (O&M) costs will be reduced as well.

Using the Active Wake Control techniques an increase in energy yield of about 1.5% is achievable, depending on the wind turbine, lay-out of the wind farm and the local wind conditions. Also the wind characteristics in the wake are less turbulent reducing the fatigue loading substantially (up to 5%). This will reduce the CAPEX by saving on material cost, and reduce the O&M requirements and subsequent down time for the highest loaded machines (or extend lifetime). Another effect that will lead to a substantial lower Cost of Energy is that, due to more accurate predictions of the total energy yield and the loading of the individual wind turbines in a wind farm, the risks of a far offshore wind farm project are substantially reduced, which results in a lower WACC. A cost reduction of 2.4% from technical innovations has been derived using the FLOW cost model. The model also shows the potential of an additional 3% reduction due to lower cost of capital.

Presentation

![]() Windkracht 14: Integrated wind farm design

Windkracht 14: Integrated wind farm design

Link

Power and loads for wind turbines in yawed conditions

Partners involved

- 2-B Energy

- ECN

- ENECO

- RWE

- TU Delft

- XCMC-Darwind

Contact details

Mr. Toine Curvers

Share this page

Share this page