◀ Back to projects overview P201305_006_XD

XEMC Darwind Next Generation offshore wind turbine (7-8 MW)

In the past years, XEMC Darwind and XEMC Windpower have successfully designed two wind turbines in the range 4 to 5 MW: the XE128-5MW and the XE140-4MW. The XE128 will be installed in a first offshore wind farm of ten units in the Pinghai Bay project, China.

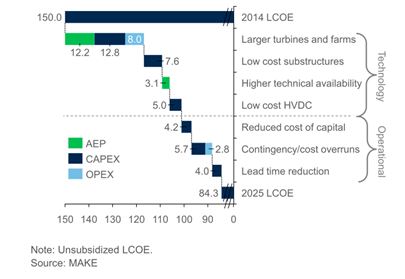

The wind energy sector however, is still going through a process of increasing rotor size and rated power, of which the end point is not yet clear. More than half of cost of energy decrease is expected to be due to turbine and farm upscaling, according to MAKE consulting (see Figure 1).

In this FLOW project, XEMC Darwind has performed major steps in increasing turbine size from 4-5 MW to 7-8 MW, which will contribute significantly to cost of energy decrease.

A significant amount of innovations is present in this project. In order to control risks, it has been decided to carry out the project in two stages:

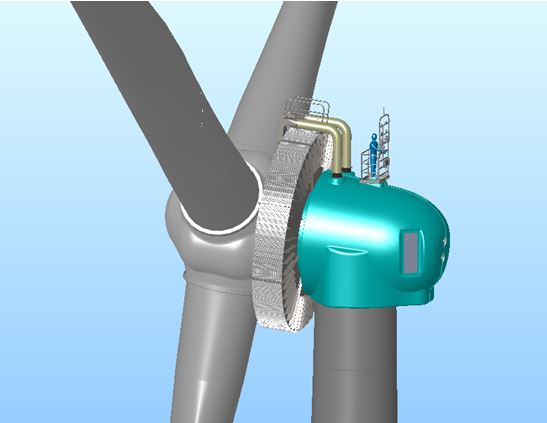

- Design and construction of a 4 to 5 MW turbine with no upscaling risks, but with all other innovations envisaged in the upscaled turbine.

- Design and construction of a 7 to 8 MW Next Generation Turbine with a lower cost of energy.

In this project, said innovations have been defined in four systems in focus:

- Generator

- External yaw drives

- Streamlined nacelle

- Optimal bearing concept

A segmented generator has been researched, enabling upscaling while keeping production costs in check and with attention to installation. The external positioning of the yaw drives allows for much more flexibility in keeping the higher yaw moments of an upscaled turbine in check. The streamlined nacelle configuration keeps nacelle weight down, while also providing space for external yaw drive maintenance. Finally, the optimal bearing concept research provides steps in the direction of reduced bearing costs.

In this project, important steps in the design of innovative solutions for these four systems in focus have been made, contributing to R&D line 4.2 (design and control tools) and 4.3 (mechanical and electrical concepts). These steps should enable the next stage, the design of the 4-5 MW turbine (see Figure 2), to be carried out swiftly. This in turn will enable upscaling to a 7-8 MW turbine (outside the scope of this project), which will allow customers from XEMC Darwind/ XEMC Windpower to benefit fully from economies of scale in offshore installation and operation & maintenance. These economies of scale will finally allow for a landmark reduction in levelized cost of energy (LCOE) of over 10%, as quantified using FLOW cost models. Also, higher water depths will become economically feasible for wind energy development with these larger turbines.

Contact details

Mr. Marco Plantema

Share this page

Share this page